There are many diverse applications and uses for catalysts of which these are some specific examples.

Fluid catalytic cracking (FCC)

Fluid catalytic cracking (FCC) is a widely used process in petroleum refineries to convert the high molecular weight hydrocarbon fractions of petroleum crude oils into lower molecular weight products such as gasoline, ethylene and propylene. Cracking of petroleum hydrocarbons was originally carried out by thermal cracking but this has been almost completely replaced by catalytic cracking because it produces more gasoline with a higher octane rating. FCC catalyst are silica/alumina zeolite based.

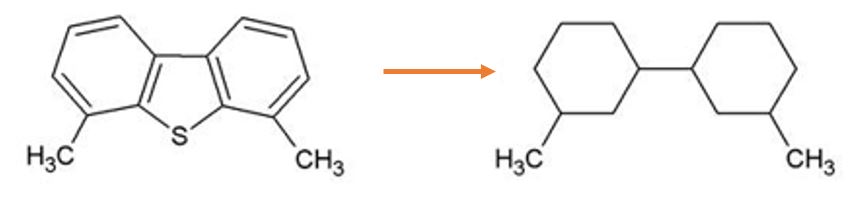

Hydrotreating

More specifically hydrodesulfization (HDS) of hydrocarbon feedstocks to produce ultra-clean diesel and naphtha. The catalysts remove impurities like sulfur, and also to a lesser extent nitrogen, oxygen, contaminant metals like Ni, V, Fe, and As, and aromatics from the hydrocarbon feedstock. The process of hydrodesulfurization of feedstocks is one of the reasons society was able to overcome the acid rain problems of the 1970’s and 1980’s. Indeed, compliance with European Directive on fuel quality has only been achievable with the use of cobalt containing catalysts. Additionally, the use of highly efficient cobalt-containing catalysts is beneficial for the environment. Using such catalysts, reactions can be performed at lower temperature, lower pressure and/or producing less by-products. The use of such catalysts is therefore both environmentally friendly and cost/resource efficient.

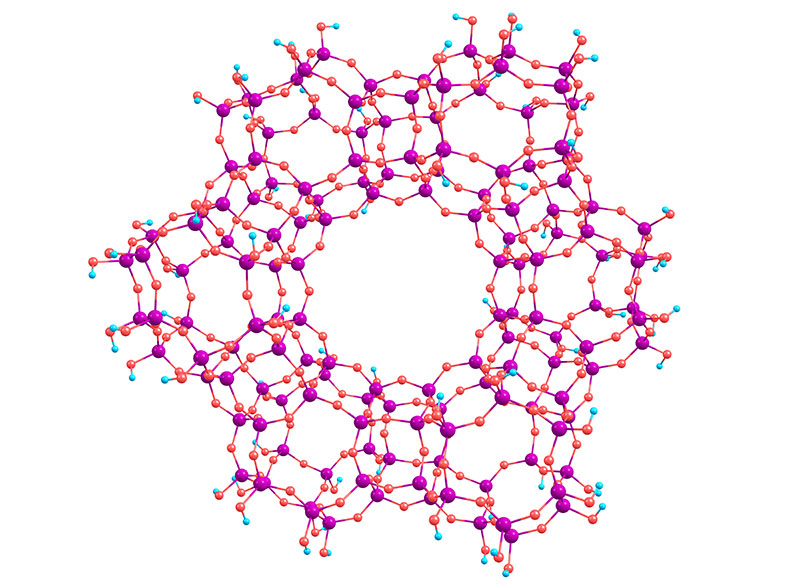

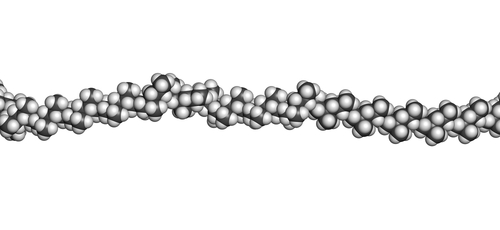

Polymer production

The production of polymers is one of the mostly wide used applications for catalysts. Polyolefin polymers such as polyethylene produced from ethylene are typical examples that utilise high specialised catalysts for production. The most common catalysts are called Ziegler-Natta catalyst named after the researchers who developed them. They are a transition metal compound bearing a metal–carbon bond able to promote a repeated insertion of olefin units and thus generate a macromolecular polyolefin chain. Usually, the catalyst system consists of the combination of two components: a transition-metal compound, most frequently a titanium halide, and a main group metal alkyl, generally an aluminium alkyl or alkyl halide, and can comprise additional components such as electron donors.

Syngas production

The catalysts used for syngas production are generally focused around: cleaning the feedstock, converting the hydrocarbons in the feedstock, and finally polishing for the subsequent synthesis reactions. This requires different catalysts with different compositions and shapes to get the most efficient use of natural resources.

Power-to-X (PtX)

The catalysts used in the PtX industries are mainly focused around the different synthesis reactions depending on the end product. This requires different catalysts with different compositions and shapes to get the most efficient use of the available power. The quality of the CO2 being used may also require special catalysts in order to clean it.

Automotive emissions control

Catalysts are widely used for emissions reduction in automobiles. This is a specialized area not followed by Catalysts Europe. See Association for Emissions Control by Catalyst (AECC) www.aecc.eu