Many catalyst applications involve full containment of catalysts and very limited exposure to workers. In the case of solid heterogeneous catalysts, they are used typically in fixed reactors where the catalyst is contained in a vessel with no risk.

The main risk of exposure is during loading and unloading of the catalyst which may be an infrequent operation and carried out be specialist catalyst handling companies. Catalysts Europe have worked with catalyst handling companies to develop a catalyst handling best practice guide. This guide is intended for users, handling companies and designers of catalyst systems. It covers catalyst specific guidance and is designed to supplement general safety practices.

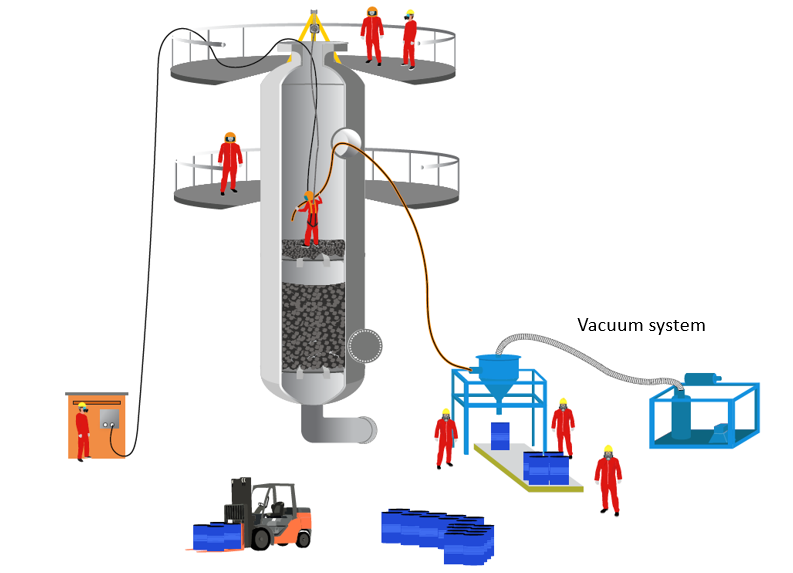

Catalyst Unloading

This drawing illustrates spent catalyst unloading by gravity into containers.

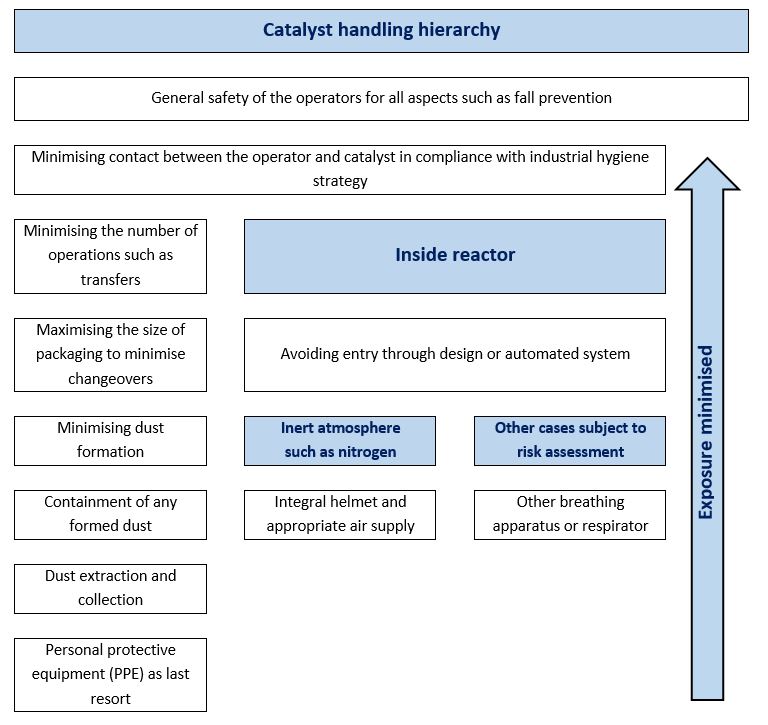

Catalyst loading hierarchy

This gives an overview of the preferred options in the handling of catalysts. The choice will depend on the particulars of the installation and the equipment available.

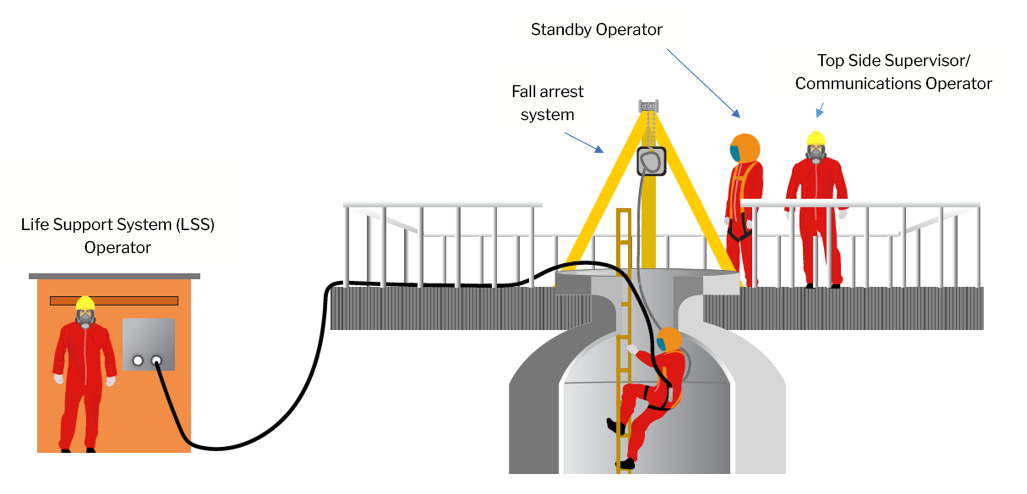

Entry into a reactor

In some cases, entry into a reactor is unavoidable. In this case, an integral helmet and appropriate air supply is required. This is high risk operation and strict procedures are required including the specialised equipment, supervision and training required.